One of the most important aspects of safety at a power plant or power and heating plant is ensuring appropriate fire protection. The transformation of fuel into energy which takes place at power plants and the quantity and variety of flammable substances occurring in the elements of the technical infrastructure of the building generate a very high risk of the occurrence of fire, and may also impact the speed with which it spreads. In order to prevent breaks in the production of electrical energy and damage to the plant, specialist fire protection solutions should be applied in each sector of the structure.

The full range of active fire protection solutions we offer combined with our many years of experience and engineering know-how mean that we can design and execute comprehensive fire protection systems for any type of power plant.

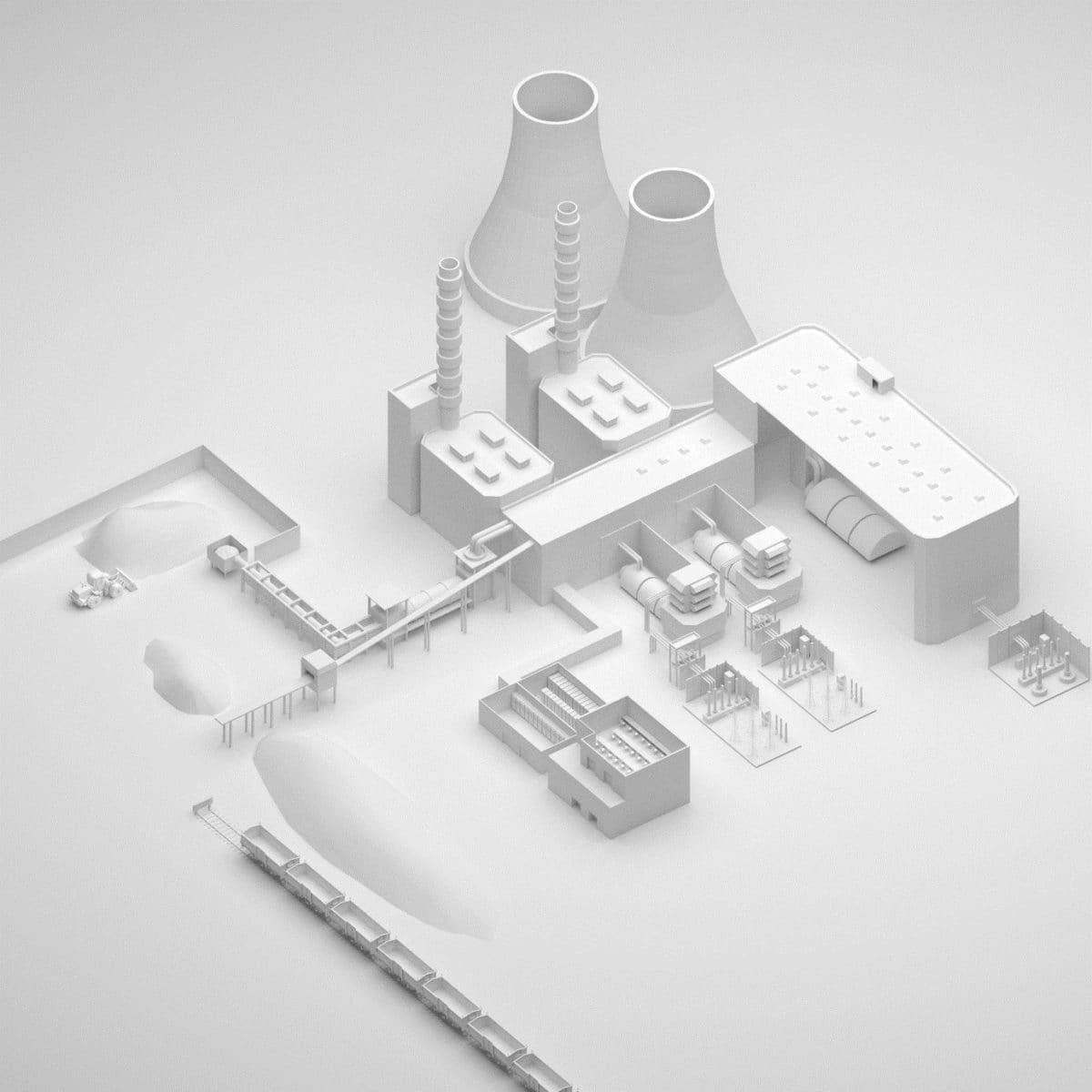

Below we present recommended fire protection solutions for individual zones of the power plant.