Losses caused by fire include not only damage to the production line, machinery and devices, but also losses resulting from the forced standstill of production. Even a small fire can paralyse the operation of the entire production plant and temporarily delay or block the realisation of orders. This may directly result in the loss of current clients.

For this reason, it is essential to ensure adequate fire protection for individual machines and devices, production lines, and entire production plants. The full range of active fire protection solutions we offer combined with our many years of experience and engineering know-how mean that we can design and execute comprehensive fire protection systems for any type of production plant and any industry.

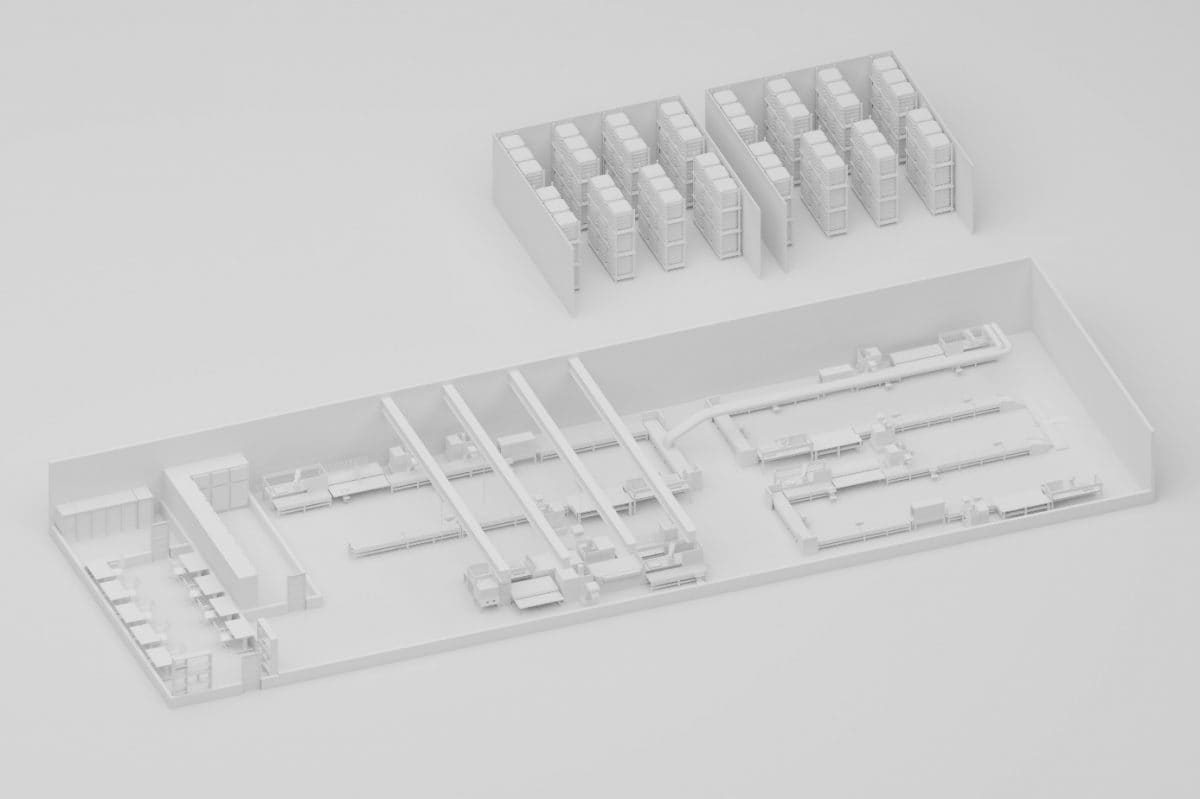

Below we present recommended fire protection solutions for individual zones of the production plant.